Accueil | Integrators

INFRARED TECHNOLOGIES FOR INTEGRATORS

You sell turnkey surface treatment solutions. Your customers are demanding and you need innovative infrared drying technologies. We offer you the opportunity to include them in your offers so as to widen your product range.

Your priority: expertise and reliability

Y

ou are looking for infrared drying expertise, a partner that you can trust for?

Objectives

You need a highly reliable solution so as not to take any risks with your brand’s image.

- Excellent support when you need it.

- Operations around the world.

- Technological training for the integration of your products.

Our services dedicated to integrators

Pre-sales advice and expert support for your customers

- A single contact-person with expertise in the sector (glass, plastic, metal, aluminium, composite, textile, etc.)

- We study the performances of our technology for all types of coatings (paint, varnish, glue, mastic) and all types of surface

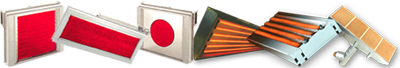

Technologies for industrial infrared drying

- 20 instruments covering a large gas and electrical range at a variety of powers

- 4 technologies: Gas fired radiant unit / Gas catalytic fibrous radiant burner / Ceramic gas catalytic radiant unit / Electrical radiant burner

Technical support

- Sizing help

- Support with design and integration

- On-site activation of your customers’ drying unit

- Repairs – After-sales support

Training

- Training sessions in our infrared technologies, handling and testing of our drying ovens in our show room

- Calculation and sizing method

- 1st level maintenance and repairs

Special access with technical fact sheets

- Provision of regularly updated technical fact sheets (product specification, throughout and power, external dimensions and integration methods)

- Examples of product files with drying time and productivity increases.

- Provision of 3D and 2D plans and samples of previous industrial oven installations

Advantages

The advantages of infrared technology

Reduced drying time : up to 4 times faster

Increased productivity

Energy efficiency : performance 40% higher

Safety in an atmosphere with solvents : flameless technology thanks to our Thermoreactors® and Catherm®

Finishing quality

Cleaning up pollutants and solvents through catalytic combustion and out Air Recycling System technology

Energy saving and strong reliability in an aggressive atmosphere with our range of Ceratherm electric emitters

Strengths

Sunkiss Matherm’s strengths

Inventor of flameless gas infrared radiant unit: the Thermoreactor®

Excellent technical support when you need it

Operations around the world

Provision of testing equipment and material hire

Figures to note …

+20

integrators worldwide60

years of expertise with infrared technology25

years integrating infrared technology solution into surface treatment20

emitters multi-technology infrared in the range400

m2 of testing facilities, provision of testing equipment, gas or electrical48

h Customer support for customers holding contractsApplication samples

| Scope of application | Technical solution provided | Benefit gained |

|---|---|---|

| Powder paint | – Tunnel furnace for truck chassis stiffeners – Replace electrical IR with our Catherm (R) technology |

Cut energy consumption by 3 |

| PVC floor covering | – Replace an electrical technology with our band Ceratherms | – 30% less energy consumption |