Accueil | Your requirements > New installation

DESIGNING AN INDUSTRIAL DRYING TUNNEL

Many industrial sectors require drying equipment. Sunkiss Matherm, which specialises in infrared radiant units and inventor of the Thermoreactor®, offers you a tailor-made drying tunnel. The No1 goal is improve the quality of your coating and the performance and reliability of your oven.

For every requirement:

an efficient and tailor-made drying solution

F

or your manufacturing business you need efficient equipment for drying, browning on or browning. You have space restrictions, need to conserve energy and want to cut drying time or boost performance.

- "

I apply paint and I need a polymerisation unit to dry paint, ink or varnish on all kinds of surfaces”

- "

I am looking for an efficient and safe technology for applying gratin to my food products”

- "

I would like a unit that is capable of speeding up the drying process for my fabric for my technical fabrics”

Objectives

Your drying tunnel has to be installed in a way that meets the following goals:

- Saves energy while reducing your CO2 emissions.

- Reduce the overall dimensions of our drying equipment.

- Increase your productivity.

- Improve your finishing quality.

Designing drying technology : our approach

Customer contact

- A single contact-person, with expertise in your sector (glass, plastic, metal, aluminium, composite, textile, etc.)

- Performance review of our technology for all types of coating (painting, varnish, glue, mastic) and all types of surface

Testing on your site with our mobile infrared emitters or in our SUNKISS test centre.

- Performance tests with our range of infrared emitters

- Performance validation after testing in your industrial environment

Sunkiss Matherm is the only manufacturer that offers both electric and gas infrared solutions.

Solution qualification and sizing, budget proposal

- Optimisation of the isntallation of infrared radiant unit and setting appropriate power

- Costing of your project with deadline commitment

Technical and operational design

- Our design team devise your turnkey infrared drying tunnel

- Comprehensive design and construction supervision of your project by our experts

Equipment delivery, installation and commissioning

- Pre-assembly and pre-acceptance of the unit in our workshops

- Work on your site (fast, thanks to pre-assembly in our workshops)

- Commissioning according to your acceptance report

Training

- We will train your maintenance or production team either on your site on our premises

- We will provide you with a user and maintenance manual for your infrared equipment

Equipment warranty

- Our equipment comes with a 2-year warranty and an option to extend that with a maintenance contract

Advantages

The advantages of infrared technology for drying

Reduces drying time : up to 4 times faster

Energy efficiency : performance 40% higher

Safety in a solvent-based atmosphere : a catalytic flameless technology thanks to our Thermoreactors® and Catherm®

Higher finishing quality for your paint and varnishing

Cleaning up of Volatile Organic Compounds through the catalytic combustion involved in our Air Recycling technology (patented system)

Reduces the overall dimensions of your unit

Increases your productivity.

Strengths

SUNKISS MATHERM strengths

The inventor of the flameless gas infrared radiant unit: Thermoreactor®

A turnkey unit with our performance commitment

We understand your business needs thanks to our expertise across a variety of sectors

Figures to note …

60

years expertise in infrared technology for industry25

years of integrating technological solutions into surface treatment20

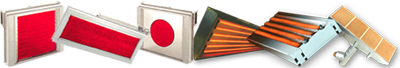

émetteurs multi-technology infrared transmitters in the range400

m2 of testing facilities, nearly 20 test nits and stands, both gas and electric48

h technician on site within for customers with maintenance contracts2

years warrantyExamples

| Scope of application | Technical solution provided | Benefits gained |

|---|---|---|

| Liquid painting on aircraft engine nacelles | Drying oven with Thermoreactors® infrared emitters | – Increased productivity – Improved painting finish |

| Liquid varnish on glass bottle | Spray booth and industrial drying tunnel | – Increased productivity – Reduced size |

| Powder paint on metal sections | For high power drying Catherm® | – Compact drying tunnels – Saves energy (consumes less) – Less clutter (free up space) |