Accueil | Your requirements > Improve process and equipment

BOOST THE PROCESS AND EQUIPMENT

You use a drying oven for your industrial activity (painting, food, automobile, fabrics for techncal uses, etc.). Your aims change and so do your performance needs. Sunkiss Matherm can help you optimise your infrared unit in accordance with your particular needs.

Upgrade your infrared drying oven

Y

ou want to improve your process without jeopardising your investment. Transform the existing unit will enable you to achieve several goals :

Objectives

- Substantially reduce drying time.

- Widen your unit’s scope of application (part sizes, new materials, etc.).

- Reduce your costs: save energy, increase productivity and optimise space.

- Limit maintenance of your infrared oven and standardise spare parts.

- Improve finishing quality: better surface treatment and reduction in amount of refuse.

- Control VOC discharges.

Offers for improving your industrial drying oven

Audit/benchmarking

- Analysis of the current performances of your oven compared to productivity references

- Opportunity reports, performance validation (tests)

- Upgrade recommendations

- ROI

Part replacement / update

Examples :

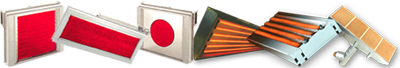

- Boost drying by fitting a recycling infrared emitter (Thermoreactor® VRX) into the existing unit

- Replace installed radiant units by an innovative ceramic technology (Catherm®)

Turnkey project, move

Interventions during cessation of production

- Dis-assembly of existing infrared unit

- New technology fitted

- Performance check

Advantages

The benefits for your company

Enjoy targeted innovations without needing to change all your equipment

Address productivtion constraints (e.g. several part sizes)

Adapt the existing process to new materials

Strengths

SUNKISS MATHERM’S strengths

Reduces drying time (tup to 4 times faster)

Boosts energy efficiency: performance 40% higher thanks to Catherm® technology

Extra safety thanks to flameless catalytic technology

A pluri-discipinary technical team

Figures to note …

60

years expertise in infrared technology for industry25

years of integrating technological solutions into surface treatment20

emitters multi-technology infrared in the range400

m2 of testing facilities, nearly 20 test nits and stands, both gas and electric48

h Technician on site for customers with maintenance contracts2

years warrantyExamples

| Scope of application | Technical solution provided | Benefit gained |

|---|---|---|

| Powder paint |

– Tunnel furnace for truck chassis stiffeners |

Cut energy consumption by 3 |

| PVC floor covering | Replace an electrical technology with our band Ceratherms | -30% less energy consumption |